Our mission:

We proudly serve the design industry since over 20 years as freelancers, mostly onsite. Now we decided to aim for something bigger. We founded this company to deliver superior services in all categories from concept modeling up to class A release data, VR presentations, still renderings and animations. Our latest addition to our portfolio is a industrial 3d SLA printer to roundup our services. Our highly experienced staff will deliver, even on the most demanding projects.

Professional design service :

Process:

If your company already uses Autodesk Alias software, you know that it is the premium modeling software for complex surfaces shapes, and is used extensively in automotive, marine, packaging and product design.

It’s a design software that is best used for freeform designs where aesthetic criteria are paramount, and where engineering CAD systems struggle to achieve the subtle sculptural shapes required.

Hire professinals onsite

Workstation, software and skills. A consultant will join your team offering the expert Alias modelling skills you need to complete your design.

Remote CAD support

We work from our office. Data transfer is either managed by your company via secure VPN connections, or via out secure FTP server.

Creative Control

Throughout the process we feedback 3D designs so that you have full creative control of the final product. VR presentaions can be prepared and shown in our office.

Quality Control

Unlike a contract agency, you know the individual designer who will support your project.

Nevertheless, its just a tool. Like with most other applications, its the person who masters the tool. We work with Alias in the most demanding environments since decades and never failed to deliver.

We act with ease in the challenging field between design and engineering to help finding the best possible solution.

We have integrated powerful CAD-software into our design process ever since – either for rough conceptual models or ready-to-process class-A-surfaces. Our highly skilled Alias-Modelers are designers themselves with a great understanding for geometry and being able to read hand drawings. We provide you with the best quality surface data for your ongoing engineering or molding work.

Software for CAS/surfacing:

Alias Surface, ICEM Surf, Modo

3D printing :

The process we use:

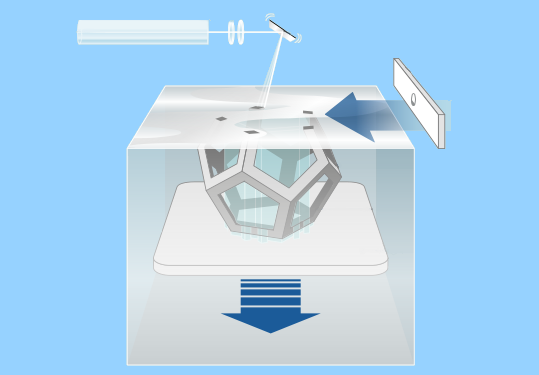

The most commonly used technology in this processes is Stereolithography (SLA). This technology employs a vat of liquid ultraviolet curable photopolymer resin and an ultraviolet laser to build the object’s layers one at a time. For each layer, the laser beam traces a cross-section of the part pattern on the surface of the liquid resin. Exposure to the ultraviolet laser light cures and solidifies the pattern traced on the resin and joins it to the layer below. After the pattern has been traced, the SLA’s elevator platform descends by a distance equal to the thickness of a single layer, typically 0.05 mm to 0.15 mm. Then, a resin-filled blade sweeps across the cross section of the part, re-coating it with fresh material. On this new liquid surface, the subsequent layer pattern is traced, joining the previous layer. The complete three dimensional object is formed by this project. Stereolithography requires the use of supporting structures which serve to attach the part to the elevator platform and to hold the object because it floats in the basin filled with liquid resin. These are removed manually after the object is finished.

What is 3d printing ?

3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file. The creation of a 3D printed object is achieved using additive processes. In an additive process an object is created by laying down successive layers of material until the object is created. Each of these layers can be seen as a thinly sliced horizontal cross-section of the eventual object.

3D printing is the opposite of subtractive manufacturing which is cutting out / hollowing out a piece of metal or plastic with for instance a milling machine. 3D printing enables you to produce complex (functional) shapes using less material than traditional manufacturing methods.

-

automotive

-

consumer products

-

medical

-

toys

-

art

-

lighting

-

accessories / jewelry